Electric vehicle battery development

Has been a hot topic in recent years. Researchers are exploring various materials and designs to improve the performance of batteries. One such material is fluoride-containing electrolyte, which has been developed for lithium metal batteries. This material could potentially boost the electric vehicle industry.

Solid-state batteries are another area of research that could be key to achieving the widespread adoption of electric vehicles. A team of researchers from MIT and the University of California at Berkeley has demonstrated the importance of keeping future low-cost, large-scale manufacturing in mind when exploring novel battery concepts.

|

| EV Battery |

Lithium-ion batteries, which are currently used in electric vehicles, have limitations that persist, in part because of their structure. Researchers are changing key features of the lithium-ion battery to make an all-solid, or “solid-state,” version. They replace the liquid electrolyte in the middle with a thin, solid electrolyte that’s stable at a wide range of voltages and temperatures. With that solid electrolyte, they use a high-capacity positive electrode and a high-capacity, lithium metal negative electrode that’s far thinner than the usual layer of porous carbon.

The cathodes market analysis firm, Avicenne Energy, projected that the 2020 production volume of cathode materials was approximately 500,000 metric tons. Lithium metal oxides (LiMO) have been the work-horse cathodes for at least the last four decades and will continue to be on the materials roadmap for the foreseeable future.

In summary, researchers are exploring various materials and designs to improve the performance of electric vehicle batteries. Some of the materials being researched include fluoride-containing electrolyte, solid-state batteries, and lithium metal oxides

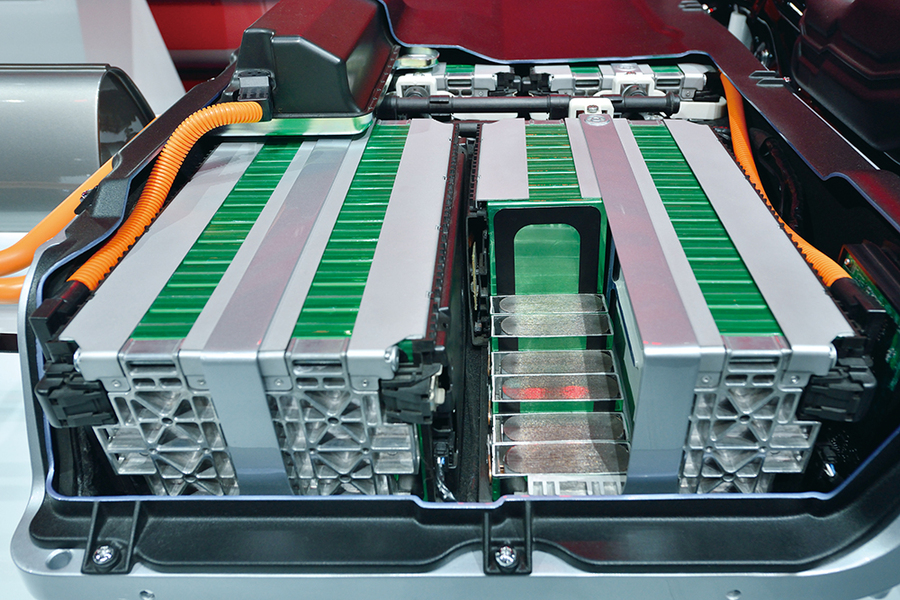

Lithium Ion Battery (Liquid Coolant System)

Lithium-ion batteries are commonly used in electric vehicles. The temperature of an electric vehicle battery system influences its performance and usage life. In order to prolong the lifecycle of power batteries and improve the safety of electric vehicles, researchers have designed a liquid cooling and heating device for the battery package. The device is able to keep each battery working at an optimal temperature under different discharge conditions by changing the flow and the inlet temperature of liquid. Large flow rates and high inlet temperatures are able to speed up the preheating process, thereby saving time of the drivers.

|

| EV Battery |

However, cooling lithium-ion battery packs is vital, as is evaluating which battery cooling system is most effective and the right electric vehicle coolant to use. The electrolyte with carbonate solvents begins to freeze in cold temperatures, resulting in the loss of ability to transport lithium ions into the anode on charge.

In summary, liquid cooling and heating devices can help prolong the lifecycle of power batteries and improve the safety of electric vehicles. However, the right electric vehicle coolant must be used to ensure the effectiveness of the cooling system. The electrolyte with carbonate solvents in lithium-ion batteries can freeze in cold temperatures, which can affect the performance of the batteries.

The Battery Performance Parameter

- SOC (Stage Of Charge)

- Battery Range Temperature Operation

- Battery Management System / Active Cell Balancing

- Charge/Discharge Rate